2023-10-26 15:17:12

Title: Finished Rolled Rebar Production Time: Enhancing Efficiency and Quality

Abstract:

This article delves into the topic of finished rolled rebar production time, exploring its significance, challenges, and potential solutions. It aims to provide readers with a comprehensive understanding of this crucial aspect of the construction industry. By examining four key aspects related to production time, this article presents insights and recommendations for optimizing efficiency and ensuring the quality of finished rolled rebar.

1. The Importance of Timely Finished Rolled Rebar Production

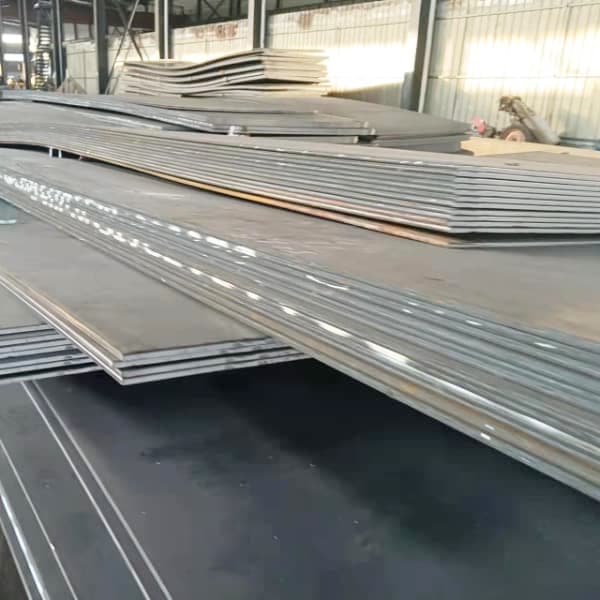

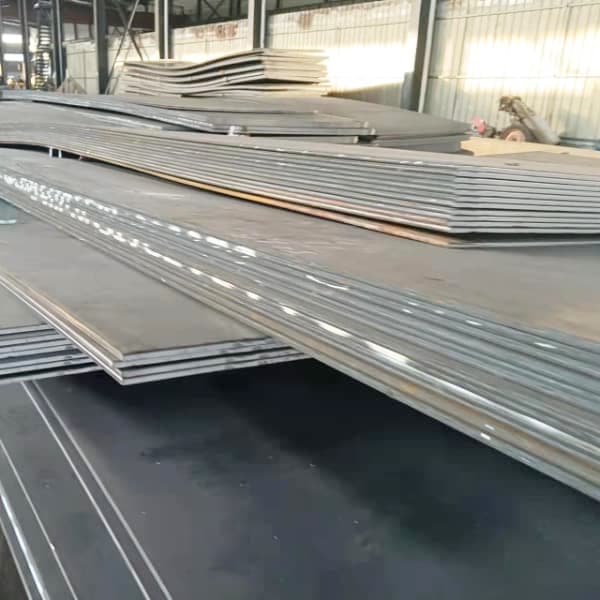

1.1 The Role of Finished Rolled Rebar in Construction Projects

Finished rolled rebar plays a vital role in reinforcing concrete structures, providing strength and durability. Timely production of high-quality rolled rebar is crucial for the smooth progress of construction projects, ensuring structural integrity and improving safety.

1.2 The Impact of Delayed Production Time

Delays in finished rolled rebar production not only disrupt construction schedules but also lead to increased costs and potential safety risks. This section explores the consequences of delayed production time, highlighting the need for effective management strategies.

1.3 Background on Finished Rolled Rebar Production Time

This subsection provides an overview of the historical context and current challenges in managing finished rolled rebar production time. It sheds light on the various factors that contribute to delays in the production process, such as material availability, machinery maintenance, and workforce efficiency.

2. Optimizing Material Procurement and Inventory Management

2.1 Efficient Procurement Strategies

To minimize production time, it is essential to establish robust procurement strategies, ensuring the timely availability of raw materials. This section explores measures such as establishing reliable supplier relationships, implementing proactive inventory management, and leveraging technology to streamline procurement processes.

2.2 Just-in-Time Inventory Systems

Just-in-time (JIT) inventory systems can significantly reduce lead time and inventory costs. This  subsection discusses the benefits and challenges of implementing JIT systems in finished rolled rebar production, highlighting the importance of accurate demand forecasting and effective coordination among suppliers, manufacturers, and contractors.

subsection discusses the benefits and challenges of implementing JIT systems in finished rolled rebar production, highlighting the importance of accurate demand forecasting and effective coordination among suppliers, manufacturers, and contractors.

2.3 Leveraging Digital Solutions

Utilizing digital solutions, such as cloud-based inventory management systems and real-time tracking technologies, can enhance transparency, optimize inventory levels, and expedite production time. This section explores the numerous benefits and potential challenges associated with adopting digital solutions.

3. Enhancing Production Efficiency through Process Optimization

3.1 Streamlining Production Processes

This subsection discusses process optimization methodologies, including lean manufacturing principles and continuous improvement techniques. By eliminating waste, reducing machine downtime, and optimizing workflow, production efficiency can be significantly enhanced, thereby reducing overall production time.

3.2 Automation and Robotics in Rebar Production

The integration of automation and robotics in rebar production has the potential to revolutionize the industry. This section explores the advantages and challenges of implementing automation technologies, such as robotic rebar bending machines and computer-aided design (CAD) software.

3.3 Workforce Training and Skill Development

Investing in workforce training and skill development is crucial to ensure that employees have the necessary expertise to maximize production efficiency. This subsection discusses the significance of continuous training programs, fostering a culture of innovation, and empowering workers to embrace new technologies and methodologies.

4. Quality Assurance Measures for Finished Rolled Rebar

4.1 Ensuring Compliance with International Standards

Adhering to international standards and codes is essential to guarantee the quality and safety of finished rolled rebar. This section explores the importance of quality control measures, certification processes, and third-party inspections to ensure compliance with established standards.

4.2 Non-Destructive Testing Techniques

Non-destructive testing techniques, such as ultrasonic testing and magnetic particle inspection, provide accurate and reliable evaluation of rebar quality without causing damage. This subsection highlights the advantages and limitations of these techniques and their contribution to maintaining high-quality production.

4.3 Continuous Improvement and Quality Management

Implementing a robust quality management system and embracing a culture of continuous improvement are essential for enhancing the quality of finished rolled rebar. This section explores methodologies, such as total quality management and key performance indicators, to monitor and improve production quality.

Conclusion:

Efficient finished rolled rebar production time is paramount for the successful completion of construction projects. By addressing the importance of timely production, optimizing material procurement and inventory management, enhancing production efficiency, and ensuring quality assurance, this article has shed light on the challenges and strategies for improving finished rolled rebar production time. As the construction industry continues to evolve, it is vital for stakeholders to embrace innovative technologies, workflows, and training programs to maximize productivity and enhance the quality of finished rolled rebar.