2023-11-10 09:00:08

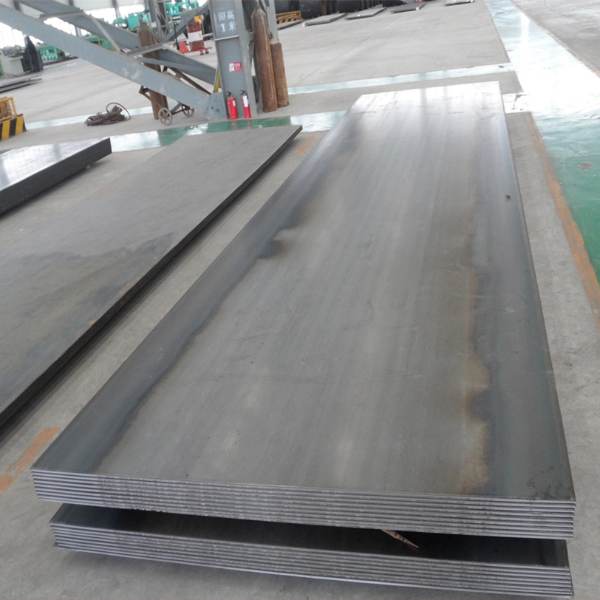

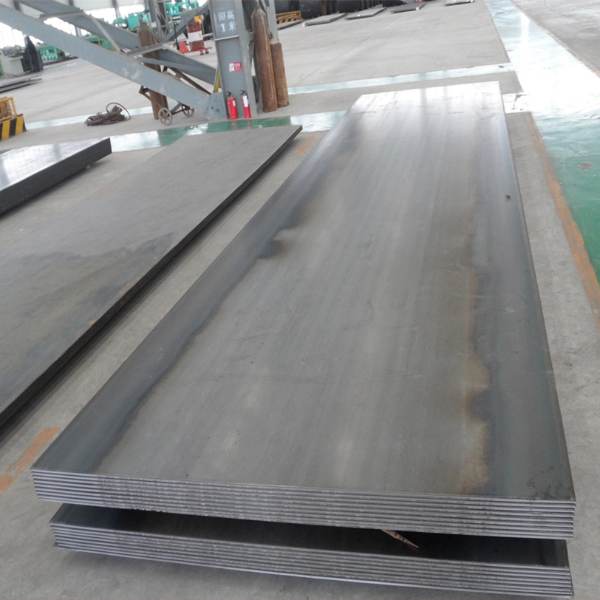

Finished rolled rebar use is a critical aspect in the construction industry. As a versatile material, it plays a crucial role in reinforcing concrete structures, enhancing their strength, and withstanding external forces. This article aims to explore the various applications of finished rolled rebar, highlighting its significance and impact on construction projects. By delving into the benefits, methods, and considerations associated with its use, readers will gain a comprehensive understanding of how finished rolled rebar contributes to the construction process.

1. Benefits and Advantages

The utilization of finished rolled rebar offers numerous benefits within the construction industry. Firstly, it enhances structural integrity by providing additional strength and support to concrete structures. This results in improved durability and resistance to external forces such as earthquakes and heavy loads. Additionally, finished rolled rebar also helps to distribute stress evenly across concrete members, preventing the formation of cracks and enhancing overall longevity.

Moreover, finished rolled rebar serves as an economical choice for reinforcement. Compared to alternative materials, such as structural steel, finished rolled rebar is more cost-effective without compromising on quality. Its availability in various sizes and shapes allows for customized reinforcement solutions, maximizing efficiency and minimizing material waste.

Furthermore, finished rolled rebar is easy to handle and transport due to its lightweight nature. This characteristic simplifies the construction process, reducing labor costs and saving precious time. Additionally, the malleability of finished rolled rebar enables it to be easily bent and shaped, facilitating complex designs and accommodating architectural requirements.

2. Applications in Construction

Finished rolled rebar finds extensive applications in a wide range of construction projects. One of the primary uses is in reinforced concrete structures such as buildings, bridges, and highways. The integration of finished rolled rebar within concrete elements, such as beams, columns, and slabs, provides the necessary tensile strength to withstand bending and stretching forces.

In addition to traditional concrete structures, finished rolled rebar is also used in precast concrete elements. These include precast panels, precast beams, and precast piles. The use of finished rolled rebar in precast elements enhances their structural integrity, ensuring a robust and reliable end product.

Furthermore, finished rolled rebar finds applications in the construction of retaining walls, tunnels, and underground structures. The  reinforcement provided by finished rolled rebar helps these structures maintain stability under various geological conditions and prevents deformations caused by soil pressures.

reinforcement provided by finished rolled rebar helps these structures maintain stability under various geological conditions and prevents deformations caused by soil pressures.

Moreover, finished rolled rebar is utilized in the construction of concrete pavements and driveways, enhancing their load-bearing capacity and ensuring long-term durability. This allows for safe and sustainable transportation infrastructure, accommodating heavy traffic volumes and adverse weather conditions.

3. Methods and Considerations

The installation of finished rolled rebar requires careful planning and adherence to specific methods to achieve optimal results. Initially, the design and specification of the reinforcement plan should consider the structural requirements, loadings, and environmental conditions. This ensures that the finished rolled rebar is appropriately sized, positioned, and secured within the concrete elements.

During construction, it is essential to follow best practices in handling and placing finished rolled rebar. Adequate support and spacing between bars must be maintained to ensure optimal reinforcement performance. Additionally, proper anchorage and lap lengths are crucial to achieve the desired bond strength between the rebar and surrounding concrete.

Considerations must also be made regarding the corrosion protection of finished rolled rebar. Various protective measures such as epoxy coating, galvanization, and concrete cover thickness should be implemented to prevent the deterioration of the rebar due to exposure to moisture and aggressive environments.

4. Future Developments and Innovations

The use of finished rolled rebar in construction continues to evolve through technological advancements and innovative research. The integration of high-strength materials and fiber-reinforced polymers (FRP) has the potential to revolutionize the performance and possibilities of finished rolled rebar. These developments aim to further enhance the strength, durability, and sustainability of reinforced concrete structures.

Furthermore, the implementation of Building Information Modeling (BIM) technology in the construction industry provides an opportunity to optimize the design and installation process of finished rolled rebar. By leveraging BIM software, contractors and designers can visualize and simulate reinforcement placement, facilitating coordinated and efficient construction processes.

In conclusion, the use of finished rolled rebar is essential in the construction industry, offering numerous benefits and applications. Its contribution to reinforcing concrete structures, enhancing their strength, and durability cannot be overstated. By understanding the advantages, applications, methods, and considerations associated with the use of finished rolled rebar, professionals in the construction industry can make informed decisions and develop innovative solutions that cater to the evolving demands of the built environment.