2023-11-24 21:38:12

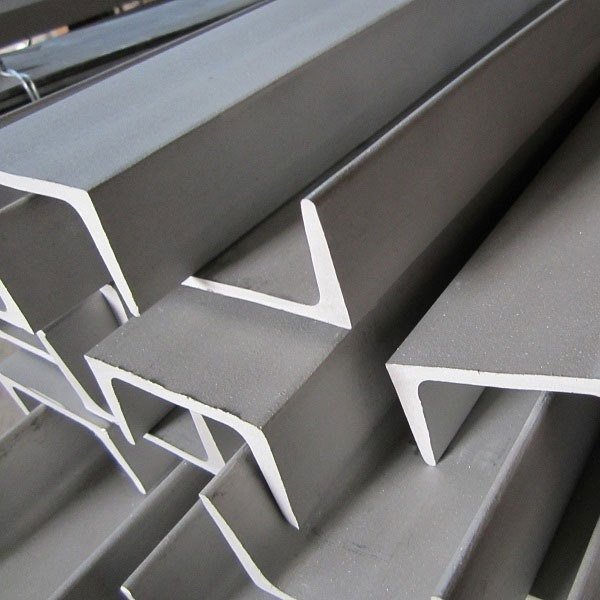

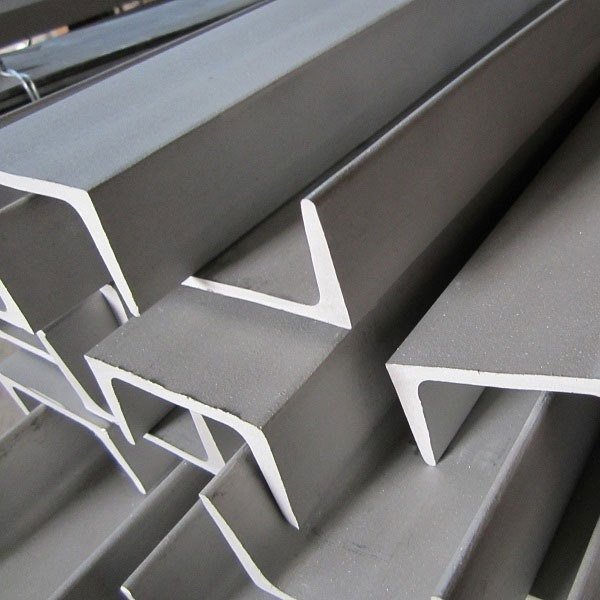

External Standard Rebar

Abstract:

This article introduces the concept of external standard rebar, providing readers with background information and igniting their interest in the topic. External standard rebar is a crucial component in construction projects, ensuring structural stability and safety. In this article, we will delve into four aspects of external standard rebar, exploring its characteristics, application, manufacturing process, and quality control. By examining these areas in detail, we aim to enhance readers' understanding of external standard rebar and its significance in the construction industry.

1. Characteristics of External Standard Rebar

External standard rebar possesses several key characteristics that make it an essential building material. Firstly, it is manufactured using high-quality steel, guaranteeing its durability and strength. Secondly, it is resistant to corrosion, ensuring the longevity of structures. Moreover, external standard rebar has excellent seismic performance, enabling buildings to withstand earthquakes and other natural disasters. Lastly, it is easy to transport and install, making it a popular choice among construction companies.

2. Application of External Standard Rebar

External standard rebar finds extensive application in various construction projects. One of its primary uses is in reinforced concrete structures, where it provides additional strength to the building. It is also utilized in the construction of bridges and highways, enhancing their structural integrity. Additionally, external standard rebar  is employed in the manufacturing of precast concrete elements, such as columns, beams, and slabs. Its versatility and reliability make it an indispensable component in the construction industry.

is employed in the manufacturing of precast concrete elements, such as columns, beams, and slabs. Its versatility and reliability make it an indispensable component in the construction industry.

3. Manufacturing Process of External Standard Rebar

The manufacturing process of external standard rebar involves several crucial steps. Firstly, high-quality steel is selected, meeting the required specifications. Next, the steel is heated and subjected to hot rolling, which transforms it into long, cylindrical bars. After the hot rolling process, the bars are allowed to cool before being cut into specific lengths. The ends of the rebar are then often ribbed to improve bonding with concrete. Lastly, the rebar undergoes surface treatment and corrosion resistance measures to ensure its longevity.

4. Quality Control of External Standard Rebar

Maintaining high standards of quality is paramount in the production of external standard rebar. To guarantee the integrity and reliability of the rebar, strict quality control measures are implemented at various stages of the manufacturing process. This includes assessing the chemical composition, mechanical properties, and dimensions of the rebar. Furthermore, multiple tests are conducted, such as tensile strength tests, bend tests, and corrosion resistance tests. By adhering to these quality control protocols, manufacturers can ensure that the external standard rebar meets all the necessary requirements.

Conclusion:

In conclusion, external standard rebar plays a vital role in the construction industry, providing strength, durability, and safety to structures. Through this article, we have explored the characteristics, application, manufacturing process, and quality control of external standard rebar. By understanding these aspects, professionals in the construction field can make informed decisions regarding the use of this essential building material. As construction technology advances, it is crucial to continually improve and innovate in the production of external standard rebar, ensuring the highest quality and performance in future construction projects.