2023-11-25 21:19:30

What is the Difference between Cold Plate and Carbon Steel Plate?

Abstract:

This article explores the difference between cold plate and carbon steel plate, aiming to provide readers with a comprehensive understanding of these two types of steel plates. By delving into the manufacturing processes, properties, and applications of cold plate and carbon steel plate, this article aims to shed light on their distinctions and help readers make informed decisions in various industries where steel plates are widely used.

1. Manufacturing Processes

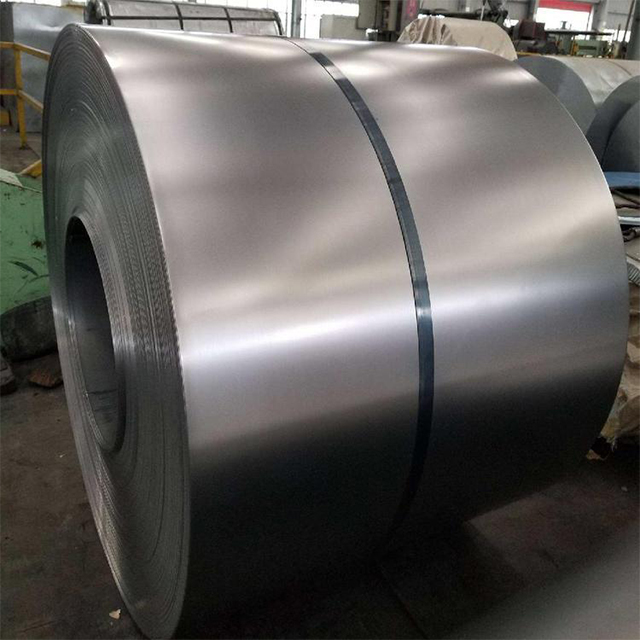

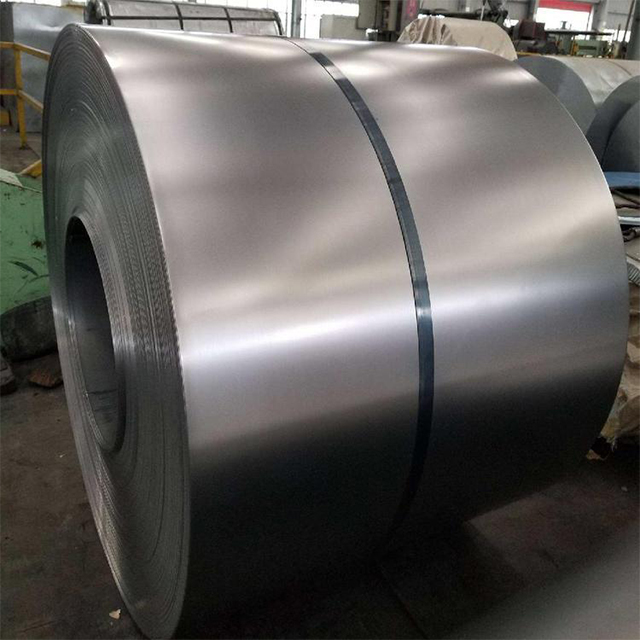

Cold Plate:

Cold plate, also known as cold-rolled steel plate, is produced through a process called cold rolling. This process involves passing hot-rolled steel through a series of rollers at room temperature, which reduces its thickness and creates a smoother surface. Cold plate undergoes annealing to improve its strength, hardness, and ductility.

Carbon Steel Plate:

Carbon steel plate, on the other hand, is manufactured through the process of hot rolling. This process involves heating the steel above its recrystallization temperature and then passing it through rollers to shape and flatten it. The hot rolling process makes carbon steel plate less smooth and increases its overall thickness compared to cold plate.

The distinction in manufacturing processes results in differences in the surface quality, thickness, and mechanical properties of cold plate and carbon steel plate.

2. Properties

Cold Plate:

Due to the cold-rolling process, cold plate has a smoother and more even surface compared to carbon steel plate. It also possesses better dimensional accuracy, making it a preferred choice for applications requiring precise tolerances. Cold plate exhibits excellent formability, enabling it to be easily shaped into various forms without cracking. It has enhanced hardness and strength compared to carbon steel plate, which makes it suitable for applications that demand high durability and resistance to wear.

Carbon Steel Plate:

Carbon steel plate, although less smooth and less dimensionally accurate than cold plate, possesses superior mechanical properties such as high tensile strength, yield strength, and toughness. These properties make carbon steel plate suitable for applications that require structural integrity and the ability to withstand heavy loads and extreme conditions. Carbon steel plate is also known for its weldability, making it an excellent choice in industries that require welded structures.

3. Applications

Cold Plate:

The smooth surface, excellent formability, and enhanced hardness of cold plate make it ideal for applications that prioritize aesthetics and precision. It is commonly used in industries such as automotive, electrical appliances, and furniture manufacturing. Cold plate is often utilized in the production of kitchen appliances, computer cases, and decorative items where visual appeal and dimensional accuracy are crucial.

Carbon Steel Plate:

Carbon steel plate finds its wide applications in the construction industry, oil and gas sector, and heavy machinery manufacturing. Its superior mechanical properties and structural integrity make it suitable for building bridges, pressure vessels, pipelines, and structural components. Carbon steel plate is also extensively used in the manufacturing of industrial equipment, machinery parts, and offshore structures.

4. Environmental Impact

Cold Plate:

Compared to carbon steel plate, the manufacturing process of cold plate consumes less energy and emits fewer greenhouse gases. Cold rolling and annealing processes require lower temperatures and less power, contributing to reduced environmental impact. Additionally, the smoother surface of cold plate requires less energy during subsequent surface treatments, such as painting or coating.

Carbon Steel Plate:

The hot rolling process used in carbon steel plate production consumes more energy and emits a higher level of greenhouse gases compared to cold plate manufacturing. The higher temperature involved in hot rolling requires more power and contributes to a larger carbon footprint. However, carbon steel plate's durability and recyclability contribute to its long lifespan and eco-friendliness throughout its lifecycle.

Conclusion:

In conclusion, the difference between cold plate and carbon steel plate lies in their manufacturing processes, properties, and applications. Cold plate, produced through cold rolling, offers better surface quality and dimensional accuracy, making it  suitable for applications that prioritize aesthetics and precision. Carbon steel plate, manufactured through hot rolling, possesses superior mechanical properties and structural integrity, making it a preferred choice for heavy-duty applications. Understanding these distinctions enables informed decision-making in selecting the most appropriate steel plate for various industries and applications.

suitable for applications that prioritize aesthetics and precision. Carbon steel plate, manufactured through hot rolling, possesses superior mechanical properties and structural integrity, making it a preferred choice for heavy-duty applications. Understanding these distinctions enables informed decision-making in selecting the most appropriate steel plate for various industries and applications.