2023-12-03 13:14:47

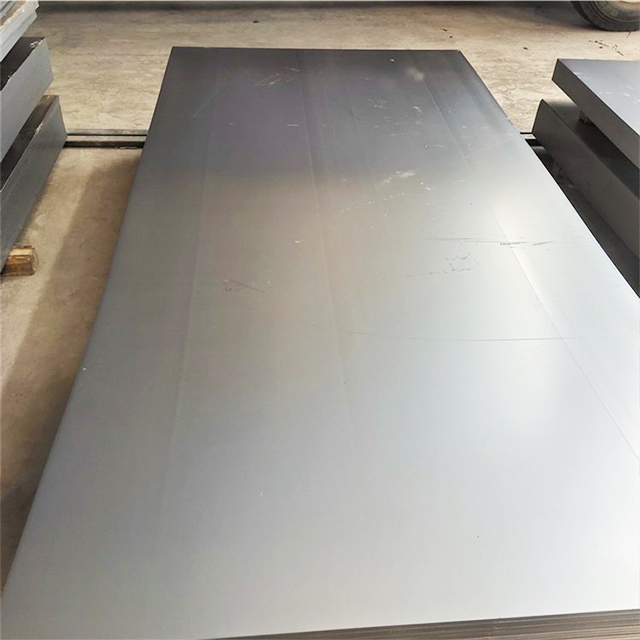

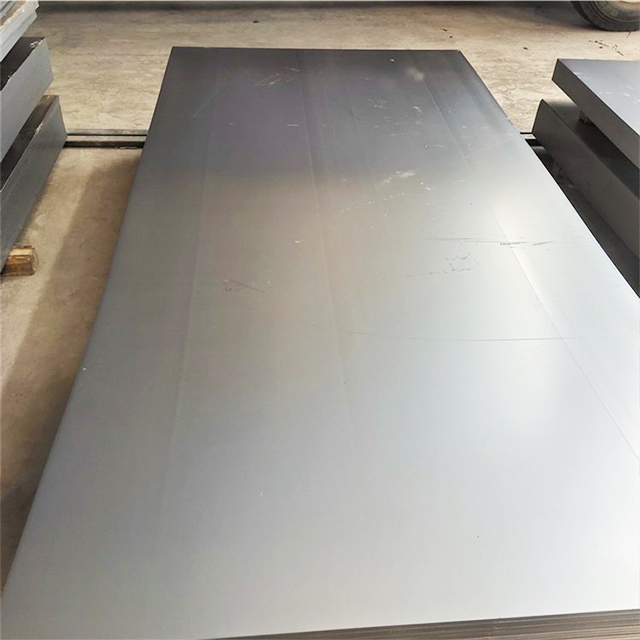

Does the Cold Plate Belong to Plain Carbon Steel?

Abstract:

The purpose of this article is to explore the question: does the cold plate belong to plain carbon steel? This topic is of interest to many readers in the steel industry, as it pertains to the classification and properties of cold plates. In order to provide a comprehensive understanding, this article will discuss the matter from four different aspects: composition, production process, physical properties, and applications. By examining each of these aspects in detail, we can determine whether the cold plate can be classified as plain carbon steel.

Text:

Plain carbon steel is typically composed of iron and carbon, with small amounts of other elements. In the case of cold plates, the composition can vary depending on the specific requirements of the application. Cold plates are often produced using low carbon steel, which contains less than 0.25% carbon. This low carbon content contributes to the desired properties of the cold plate, such as improved formability and weldability. However, there are also cold plates that contain higher carbon content, making them suitable for certain applications that require greater strength and hardness.

The composition of cold plates also includes alloying elements, such as manganese, silicon, and phosphorus. These elements are added in small amounts to enhance the properties of the steel. For example, manganese improves hardenability and strength, while silicon enhances the resistance to oxidation and corrosion. Phosphorus, on the other hand, improves the machinability and formability of the steel. Therefore, based on the composition of cold plates, it can be argued that they do belong to the category of plain carbon steel.

The production process of cold plates involves several steps, including melting, casting, rolling, and annealing. The starting material for cold plates is usually hot rolled steel, which undergoes a series of processes to achieve the desired properties. During the rolling process, the steel is cold worked, which results in the reduction of thickness and improvement of surface finish. This cold working process contributes to the enhanced strength and hardness of the cold plate. Additionally, annealing is often carried out to relieve internal stresses and improve the ductility of the steel.

It is important to note that the production process of cold plates can be modified to achieve specific properties. For example, controlled rolling and controlled cooling techniques can be employed to produce high-strength cold plates with improved toughness. These modifications in the production process indicate that cold plates are not merely plain carbon steel, but rather a specialized form of it.

The physical properties of cold plates play a crucial role in determining their classification. Plain carbon steel is known for its distinct properties, such as high strength, good formability, and excellent machinability. Similarly, cold plates exhibit these properties, albeit with variations depending on their composition and production process. Cold plates typically have higher strength compared to hot rolled plates due to the cold working process. They also have improved formability, which makes them suitable for applications that require complex shapes.

Furthermore, the physical properties of cold plates can be enhanced through heat treatment processes. For example, quenching and tempering can be employed to increase the hardness and toughness of the steel. This ability to modify physical properties suggests that cold plates should be considered as a specialized form of plain carbon steel.

The applications of cold plates further support their classification as plain carbon steel. These plates find extensive use in various industries, including automotive, construction, and manufacturing. In the automotive industry, cold plates are used for the production of body panels, frames, and structural components. Their high strength and formability make them ideal for such applications.

Similarly, in the construction industry, cold plates are employed for the fabrication of steel structures, bridges, and pipelines. The versatility and reliability of cold plates contribute to their widespread adoption in these applications. Additionally, the manufacturing sector utilizes cold plates for the production of machinery and equipment, where their excellent machinability plays a vital role.

Conclusion:

In conclusion, the examination of the composition, production process, physical properties, and applications of cold plates indicates that they can indeed be classified as plain carbon steel. The composition of cold plates, though modified to achieve certain properties, still  falls within the range of plain carbon steel. The production process and physical properties of cold plates further reinforce their classification. Finally, their extensive use in various industries provides additional evidence that cold plates belong to the category of plain carbon steel. Further research can be conducted to explore the potential advancements and applications of cold plates in the future.

falls within the range of plain carbon steel. The production process and physical properties of cold plates further reinforce their classification. Finally, their extensive use in various industries provides additional evidence that cold plates belong to the category of plain carbon steel. Further research can be conducted to explore the potential advancements and applications of cold plates in the future.